Festo Pneumatics > Helps create an innovative automated tennis ball tester.

Mecmesin a specialist in testing machines was asked to create a cost effective way to automatically test tennis balls . Mecmesin turned to Festo for help as they had supplied them pneumatic parts in the past for example their Festo linear axes and Festo pneumatic grippers as well as a PLC based system.

Festo needed to help Mecmesin to create a robust test system that could take various materials and different sized tennis balls. It also needs to reliably load and unload tennis balls into the machine. The machine would also need to be checked remotely and be able to accept new tests in the future, without needing to be redesigned.

Festo worked with Mecmesin to understand the needs of the testing machine. Once this had been done Festo recommended that their CPX integrated automation platform that also includes a PLC would be perfect for the control element. Using a Festo CPX platform means that the machine can be monitored remotely therefore allowing staff to get on with other tasks. Festo CPX automation platform, once completing a test, a test report becomes available and provides a graphical display of the results. Festo CPX automation platform is far faster and more efficient, as well as allowing the customer to add more modules later on without requiring to modify the control structure.

staff to get on with other tasks. Festo CPX automation platform, once completing a test, a test report becomes available and provides a graphical display of the results. Festo CPX automation platform is far faster and more efficient, as well as allowing the customer to add more modules later on without requiring to modify the control structure.

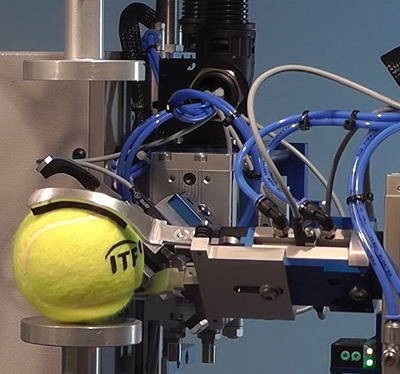

To give persistent match performance, ball samples are tested by being compressed to a specific load, and then the quantity of movement is measured. This is known as forward deformation. After this has occurred the load is then released and the return deformation is then measured. Festo precision grippers are used to guarantee that the balls act uniformly, the Festo precision grippers rotate the ball, tests are then repeated on 3 perpendicular axes. Also the weight and dimensions are also documented. A maximum of 12 balls could be packed onto the simple carousel, when testing is finished, the test report includes pass and fail criteria simplifying the interpretation of the results.

Festo also supplied the following parts to complete the tennis ball tester: Festo linear actuators, Festo operating cylinders, Festo PLC, Festo valve terminals, Festo pneumatic grippers as well as a Festo rotary table to allow the tennis ball tester to reliably perform a huge selection of tests. The customer Mecmesin were extremely happy with the final results!

To set the ball rolling on your next project or for more information on the full Festo range, call us at Electroquip today.

Mecmesin a specialist in testing machines was asked to create a cost effective way to automatically test tennis balls . Mecmesin turned to Festo for help as they had supplied them pneumatic parts in the past for example their Festo linear axes and Festo pneumatic grippers as well as a PLC based system.

Festo needed to help Mecmesin to create a robust test system that could take various materials and different sized tennis balls. It also needs to reliably load and unload tennis balls into the machine. The machine would also need to be checked remotely and be able to accept new tests in the future, without needing to be redesigned.

Festo worked with Mecmesin to understand the needs of the testing machine. Once this had been done Festo recommended that their CPX integrated automation platform that also includes a PLC would be perfect for the control element. Using a Festo CPX platform means that the machine can be monitored remotely therefore allowing staff to get on with other tasks. Festo CPX automation platform, once completing a test, a test report becomes available and provides a graphical display of the results. Festo CPX automation platform is far faster and more efficient, as well as allowing the customer to add more modules later on without requiring to modify the control structure.

To give persistent match performance, ball samples are tested by being compressed to a specific load, and then the quantity of movement is measured. This is known as forward deformation. After this has occurred the load is then released and the return deformation is then measured. Festo precision grippers are used to guarantee that the balls act uniformly, the Festo precision grippers rotate the ball, tests are then repeated on 3 perpendicular axes. Also the weight and dimensions are also documented. A maximum of 12 balls could be packed onto the simple carousel, when testing is finished, the test report includes pass and fail criteria simplifying the interpretation of the results.

Festo also supplied the following parts to complete the tennis ball tester: Festo linear actuators, Festo operating cylinders, Festo PLC, Festo valve terminals, Festo pneumatic grippers as well as a Festo rotary table to allow the tennis ball tester to reliably perform a huge selection of tests. The customer Mecmesin were extremely happy with the final results!

To set the ball rolling on your next project or for more information on the full Festo range, call us at Electroquip today.